Addr:Dongguan Mayor Anzhen Wusha Ring East Road Chen House brand building.

Tel:0769-89368511 / 33388293

Mobile:13925552470(Wechat Code)

Fax:0769-89032105

Q Q:2850923180

Email:wdp@keyangauto.com

website:en.keyangauto.com

Addr:Dongguan Mayor Anzhen Wusha Ring East Road Chen House brand building.

Tel:0769-89368511 / 33388293

Mobile:13925552470(Wechat Code)

Fax:0769-89032105

Q Q:2850923180

Email:wdp@keyangauto.com

website:en.keyangauto.com

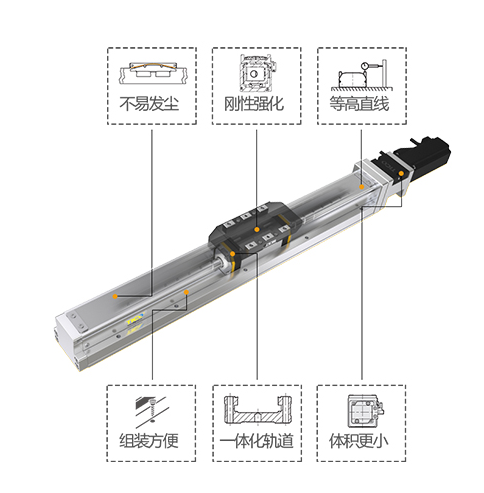

The linear module slide is composed of a combination of linear slide and motor drive. The automatic linear movement of the workpiece is realized through the motor drive. Through the combination of multi-directional axes, a motion actuator on the equipment is formed. This mechanism is often called: industrial manipulator, XYZ axis manipulator, coordinate axis slide, etc.

1. Electric linear slides are widely used in various industries

1. Entertainment industry: robotic arms and joints, dynamic seats, etc.

2. Military industry: simulated aircraft, simulation simulation, etc.

3. Automobile industry: press machine, testing equipment, etc.

4. Industrial industry: food machinery, ceramic machinery, welding machinery, spraying equipment, lifting platform, etc.

5. Medical equipment.

Second, the transmission difference

1. Ball screw drive means that the motor drives the ball screw to rotate through the coupling or synchronous pulley, and then pushes the slider fixed on the linear guide rail to move forward and backward.

a. The ball screw has the characteristics of high positioning accuracy, low friction, high rigidity and strong load capacity. Accurate positioning can be achieved.

b. In terms of speed, it depends on the speed of the motor and the size of the lead screw. The larger the lead screw, the faster the slider of the single-axis manipulator moves at the same motor output speed.

2. The synchronous belt drive is driven by the motor to drive the driving pulley of the synchronous belt to rotate, and then the belt drives the slider on the linear guide to move back and forth. The timing belt has the characteristics of low noise, fast moving speed and low cost.

In terms of speed, higher speeds can generally be achieved than ball screws. At the same time, there is no limit of critical speed, and it has more cost-effectiveness in long-stroke transmission. However, the positioning accuracy of the synchronous belt drive is lower than that of the ball screw.

(Part of the material on this website comes from the Internet. If the information displayed on this website violates the intellectual property rights or other legitimate rights and interests of media or individuals, please notify us in time, and we will delete it immediately.)