Addr:Dongguan Mayor Anzhen Wusha Ring East Road Chen House brand building.

Tel:0769-89368511 / 33388293

Mobile:13925552470(Wechat Code)

Fax:0769-89032105

Q Q:2850923180

Email:wdp@keyangauto.com

website:en.keyangauto.com

Addr:Dongguan Mayor Anzhen Wusha Ring East Road Chen House brand building.

Tel:0769-89368511 / 33388293

Mobile:13925552470(Wechat Code)

Fax:0769-89032105

Q Q:2850923180

Email:wdp@keyangauto.com

website:en.keyangauto.com

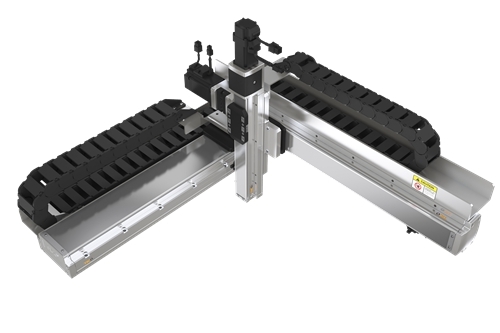

A complete linear slide module consists of slide parts and auxiliary components such as transmission brakes. The automatic duty cycle of the linear slide module is driven by a motion device mounted behind the slide. The working feed of the sliding table is realized by the working motor through the belt or the screw. According to the different transmission types, it can be divided into synchronous belt type and screw type:

Timing belt type:

The working principle of the synchronous belt type is to install the belt on the transmission shaft on both sides of the linear module, and as the power input shaft, the slider for adding the equipment workpiece is fixed on the belt. When there is input, the slider is moved by the drive belt.

Usually, the synchronous belt linear module is specially designed to control the tightness of the belt movement on one side, which is convenient for the debugging of the equipment during the production process.

The synchronous belt linear module can choose to add rigid guide rails according to different load requirements to improve the rigidity of the linear module. Linear modules of different specifications have different upper load limits. The accuracy of the synchronous belt linear module is comprehensively determined by the quality of the belt and the processing technology, and the control of power input will also affect its accuracy.

Screw type:

Ball screws are ideal for converting rotary motion to linear motion or linear motion to rotary motion. A ball screw consists of a lead screw, a nut and balls. Its function is to convert rotary motion into linear motion, which is the further extension and development of ball screw. The significance of this development is to change the bearing from rolling motion to sliding motion. Ball screws are widely used in various industrial equipment and precision instruments due to their low frictional resistance. It can realize high-precision linear motion under high load.

The main differences between them are:

Ball screw drive means that the motor drives the ball screw to rotate through the coupling or synchronous pulley, and then pushes the slider fixed on the linear guide to move back and forth. The ball screw has the characteristics of high positioning accuracy, low friction, high rigidity and strong bearing capacity. Accurate positioning can be achieved, and the repeat positioning accuracy can reach 0.005 mm. In terms of speed, it depends on the speed of the motor and the lead of the screw. The larger the screw, the faster the slider of the single-axis manipulator moves at the same motor output speed.

Synchronous belt drive means that the motor drives the driving wheel of the synchronous belt to rotate, and then the synchronous belt drives the slider on the linear guide to move back and forth. The timing belt has the characteristics of low noise, fast moving speed and low cost.

In terms of speed, generally higher speeds can be achieved than ball screws. At the same time, there is no critical speed limit, and it is more cost-effective than other methods in long-distance transmission. However, the positioning accuracy of the synchronous belt drive is lower than that of the ball screw.

Customers are choosing linear modules and need to determine which transmission mode to use based on their design requirements.